|

CUMULATIVE PRODUCTION |

300+ pieces |

|---|---|

| CAPACITY |

3 fabrication yards Monthly capacity: 16 pieces Annual capacity: 200 pieces |

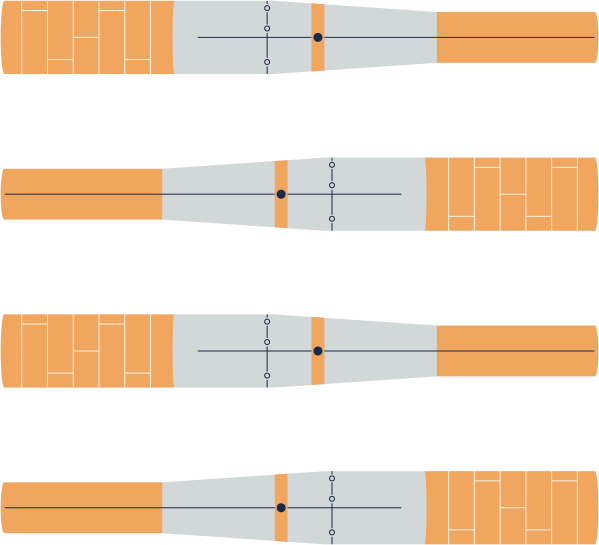

| CAPABILITIES |

Max. Diameter: 15,000mm Max. Weight: 4,500MT Max. Thickness: 260mm Max. Length: As per client's requirement |

|

CUMULATIVE PRODUCTION |

1,200,000+ MT |

|---|---|

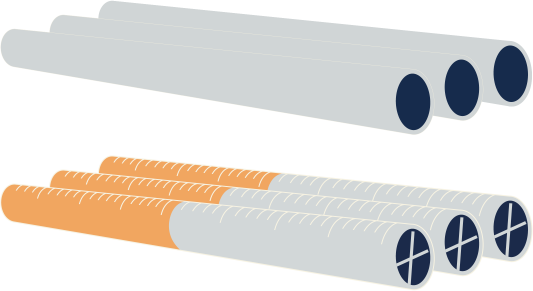

| CAPABILITIES |

Max. Diameter: 1,600mm Max. Thickness: 50mm Max. Segment Length: 12.15m |

|

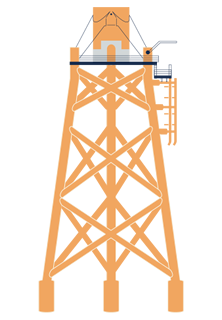

CUMULATIVE PRODUCTION |

200+ sets |

|---|---|

| CAPACITY |

1 fabrication yard Monthly capacity: 8 sets Annual capacity: 90 sets |

| CAPACITY |

2 fabrication yards Monthly assembly capacity: 3 sets Annual fabrication capacity for Subsections & Components: 180,000MT |

|---|

|

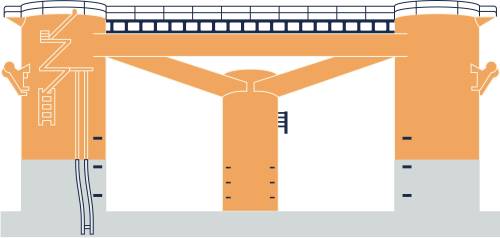

CUMULATIVE PRODUCTION |

220,000+ MT |

|---|---|

| CAPACITY |

3 fabrication yards Monthly capacity: 33,000 MT Annual capacity: 396,000 MT |